Freestanding spalled micromembranes

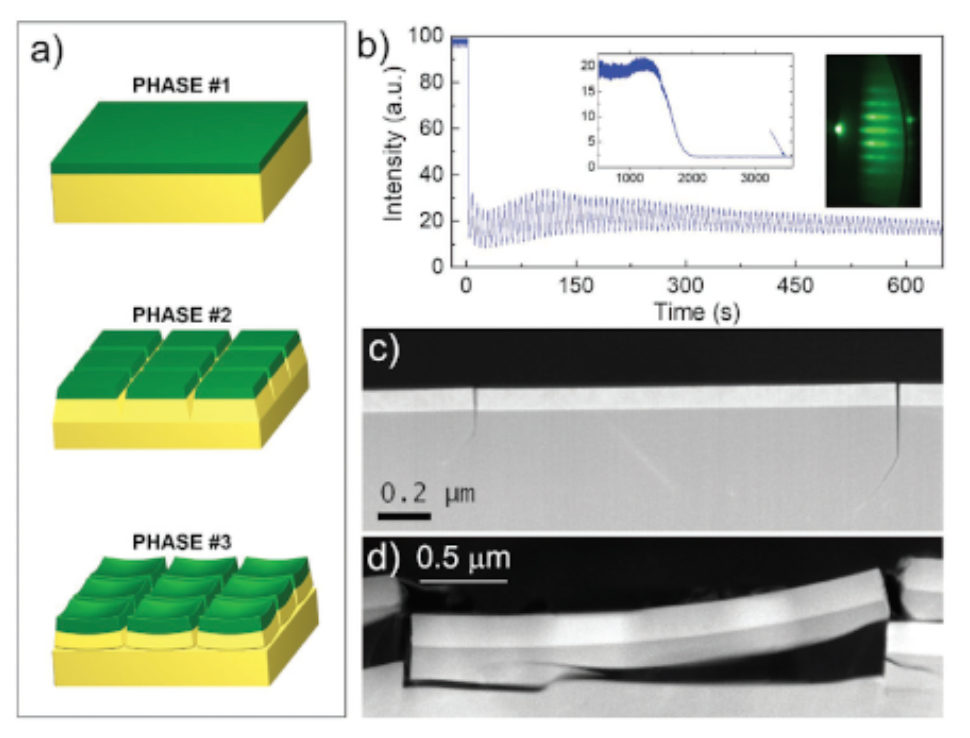

Our approach to membrane formation is based on strain engineering. By preserving the strained growth of LAO and STO well above expectations from elastic theory, we induce a devastating strain relaxation process that fragments the surface in self-formed, regularly shaped LAO/STO micro sized freestanding heteromembranes. A sketch of the process is shown in Fig.1a. The long lasting RHEED oscillations in regime of strained growth are reported in Fig.1b. Low-resolution electron microscopy HREM images of the two steps of the breaking mechanism are shown in Fig. 1c,d.

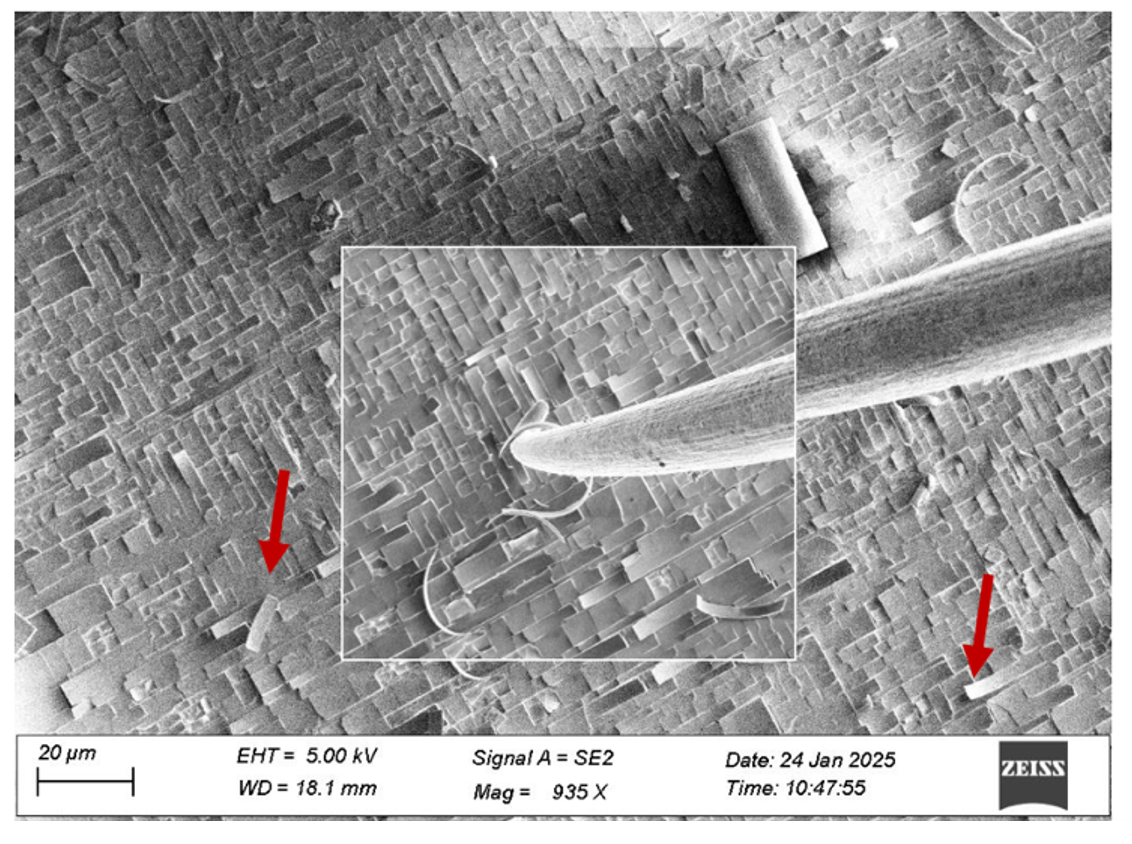

Through a collaboration with University of Copenhagen (KU) and the Technical University of Denmark (DTU), now implemented also by the employment of needles or microgripper in a SEM at CNR-SPIN Salerno (see Fig.2), we are able to select and pick up specific single membranes, then measured electrically at DTU.

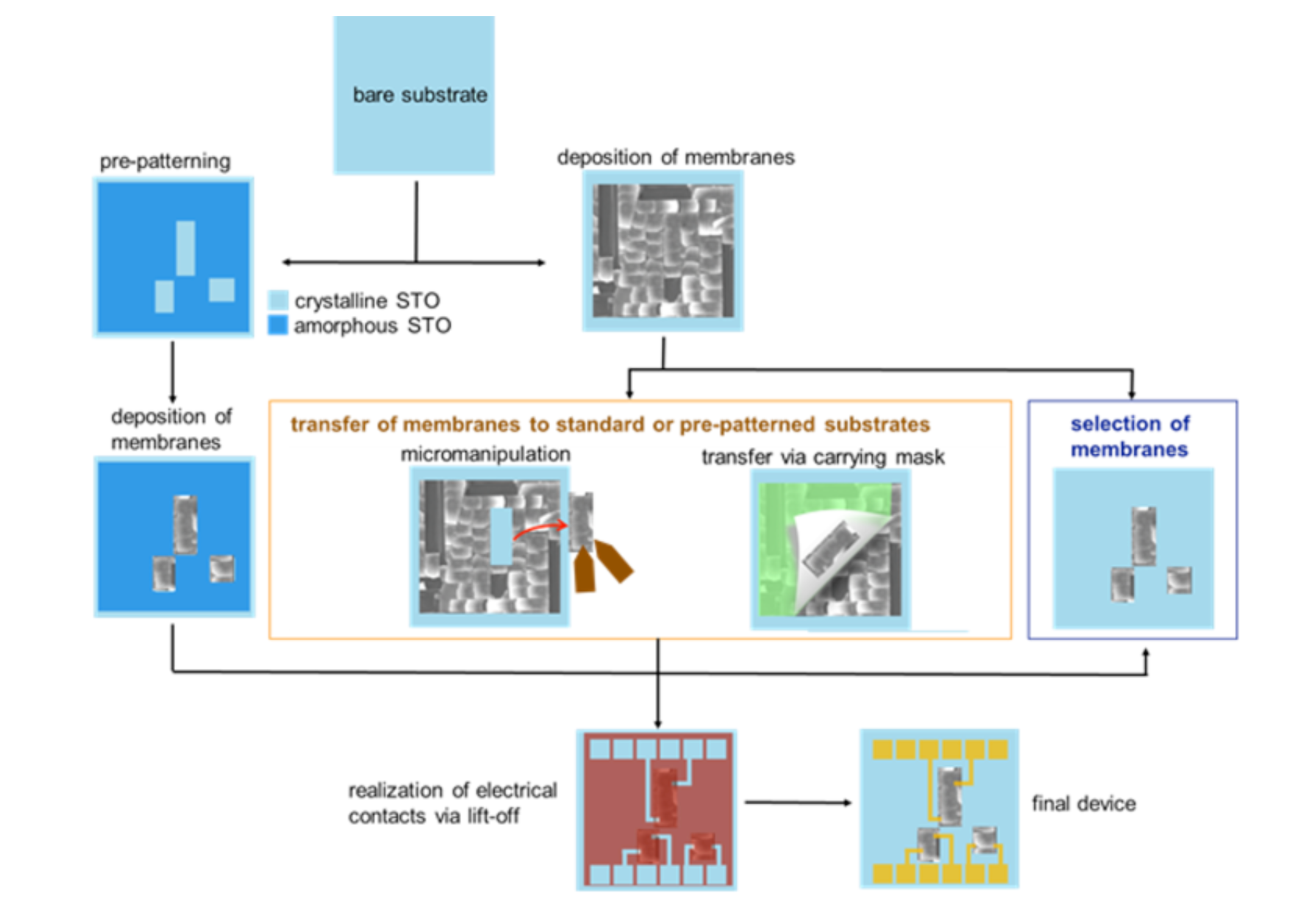

Our activity will include the preparation of prepatterned substrates for the controlled growth of membrane matrices with predefined shape, deterministic placement of membranes on chip and realization of the contacts. We will explore differeFOXESnt ways to realize membrane-based devices, as summarized in Figure 3.

Our Results